Thermal imaging has changed the way that we see and understand our world, giving us insights that were previously invisible. Thermal cameras capture infrared pictures that allow us to visualize thermal energy, detect heat and identify temperature differences. This article will examine the technologies behind thermal imaging and its applications. It will also discuss the technology involved.

What is a Thermal Imaging Camera and how does it work?

What is a Thermal Imager?

Thermal imagers, also known as thermal cameras, are devices that detect infrared radiation from objects and turn it into a visual representation called a thermal picture. Thermography, or the study of thermal energy from objects, is the basis of this technology. Thermal imaging cameras, unlike visible light cameras, detect infrared light and can visualize temperature differences across surfaces. Thermal imagers are used in many fields including electrical system monitoring, medical diagnosis, building inspections and more.

How do Infrared Camera Work?

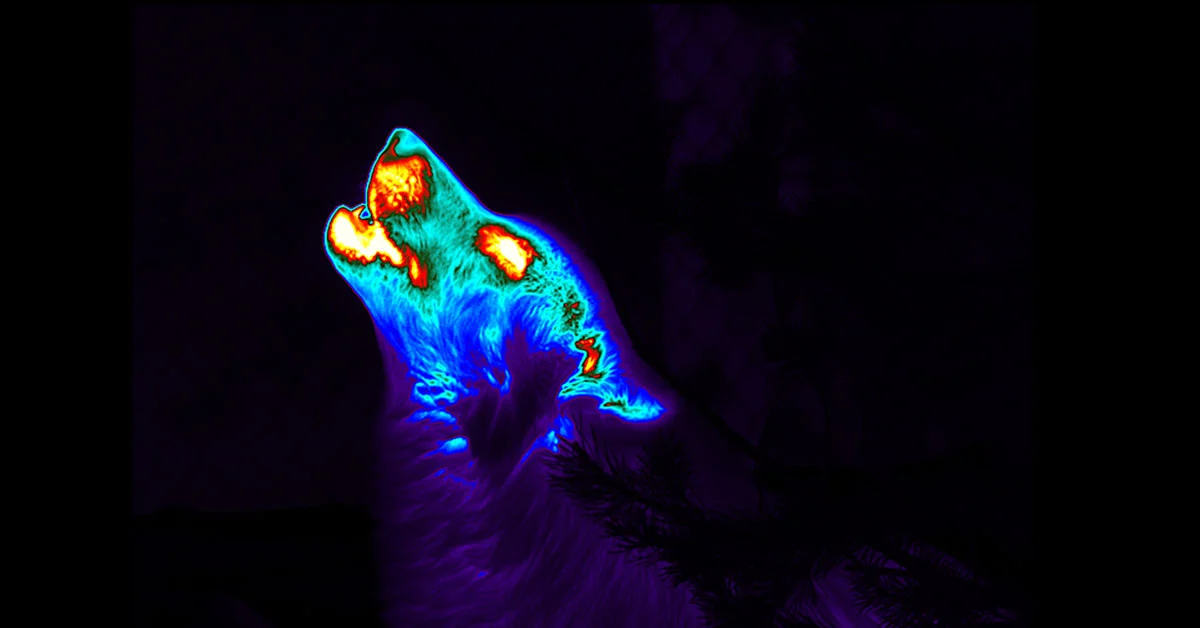

Infrared camera sensors are sensitive to the infrared spectrum. Infrared radiation is emitted by an object that emits thermal energy. This infrared emission corresponds to the surface temperature of the object. Thermal cameras use an infrared sensor to capture this radiation. The camera then generates a thermographic image based upon the detected temperature differences. Thermal imaging creates images using infrared light, which are then processed and presented in a way that makes it easy for users to interpret. The camera converts thermal energy to a visual spectrum which represents temperature variations. This allows users to identify hotspots and analyze heat loss.

What are the Parts of a Thermal Imager?

Thermal imaging cameras are made up of several components that all work together to display and capture thermal images. Infrared sensors are the primary component, as they detect infrared light. The sensors are classified into two types: uncooled thermal detectors which are used for portable thermal cameras and cooled detectors which are used in high-end applications that require greater sensitivity. The other components are an optical lens to focus the infrared light onto the sensor. A display screen is used to visualize the thermal image. Thermal cameras are also equipped with advanced features, such as image enhancement algorithms and color palettes to differentiate temperatures, along with data logging for comprehensive analysis.

How Do Thermal Images Get Captured With Infrared Technology

What is the Process for capturing a Thermographic image?

In order to capture a thermal image, the infrared camera must first detect infrared radiation from objects in its field of vision. Infrared detectors on cameras measure the intensity of radiation which is correlated to the surface temperature. The information is translated into a thermal image with pixelated values, each of which represents a temperature. Thermal imaging cameras create images using infrared, assigning shades or colors based on temperature variations. This provides a visual representation for thermal variations. Thermal scans allow users to pinpoint areas of concern such as heat loss from buildings or components that are overheating in electrical systems.

What is the Role of Thermal Energy in Thermography?

Thermography is based on thermal energy. Thermal energy is the heat emitted from all objects above absolute zero. It’s a key factor for thermal imagers. The amount of energy released by an object depends on its surface temperature, the material properties and the environmental conditions. Understanding how thermal energy behaves in thermography allows users to interpret thermal images accurately and make informed decisions using the data. Thermal imaging is unique in that it can detect and visualize thermal energies, giving users unique insights into materials and systems.

How do Thermal scans Detect temperature Differences?

Thermal cameras detect temperature differences by the infrared detector’s sensitivity. The camera detects differences in the thermal radiation that is emitted from different surfaces when it captures an image in infrared. The detector converts the temperature variations into thermal images. Users can identify areas of heat loss or overheating by analyzing thermal variations. Temperature differences can be detected accurately by a number of factors. These include the resolution of the camera, the emissivity (or heat-reflectivity) of the material being scanned and the environmental conditions.

What are the Most common Applications of Thermal Imaging and Inspection?

What is the use of Thermal imaging in Building Inspections?

Thermal imaging is a crucial tool in building inspections, as it allows inspectors to detect issues that cannot be seen with the naked eye. Inspectors can use a thermal camera to detect heat loss, moisture infiltration, electrical faults and insulation deficiencies. They can locate damaged areas quickly by visualizing temperature variations. Thermal scans, for example, can reveal hidden leaks of water that could lead to structural damage or mold growth. This information allows property owners to take the necessary corrective actions. Thermal imaging can also be used to measure the efficiency of heating systems and cooling systems. This will ensure that buildings are kept at a comfortable temperature while minimizing energy consumption.

What industries can Benefit from Thermal imaging?

Thermal imaging is used in many industries including construction, electrical and mechanical. It is used in construction to aid with building inspections and audits. Thermal cameras are used by the electrical industry to monitor electrical systems. They can identify overheating connections, and prevent potential failures. Thermal imaging is used in mechanical settings for predictive maintenance. It assesses the condition of machines and detects anomalies before costly downtime occurs. In medical diagnostics, infrared thermalgraphy is used to detect abnormal temperatures in the body. Thermal imaging has a wide range of applications that highlight its importance for enhancing safety and efficiency in multiple sectors.

What is the Role of Thermal imaging in Preventative Maintenance?

Thermal imaging can be a very powerful tool in preventative maintenance. It allows organizations to identify issues and deal with them before they become major problems. Maintenance teams can detect early signs such as wear, overheating or inefficiency by regularly performing thermal scans on equipment and systems. Thermal cameras can be used to monitor electrical panels and reveal hotspots that indicate failing components. This allows for timely repairs, which reduces the risk of equipment failures or fire hazards. Thermal imaging inspection can also help improve operational performance by identifying areas of energy loss or inefficient systems. Thermal imaging can be used to implement a proactive maintenance program that will not only reduce costs but also increase the life expectancy of systems and equipment.

What is the Best Thermal Imaging Camera?

What are the Features you Should look for When buying a Thermal Camera?

To ensure that the thermal imaging camera you choose meets your needs, it is important to consider several features. The first thing to consider is the resolution. Higher resolution cameras will capture thermal images that are more detailed, making it easier to identify temperature differences. Also, cameras with adjustable emissivity can accurately measure surface temperatures of different materials. The camera’s temperature range and battery life are also important. Thermal cameras can also come with advanced features, such as Wi-Fi connectivity, image analysis software and customizable color palettes. You can choose the best thermal camera by understanding your intended application.

What is the Effect of resolution on Thermal image quality?

The resolution plays an important role in determining thermal images. Thermal imaging cameras are measured by the number of pixels that they use to create an image. The thermal images produced by higher resolution cameras are clearer and have greater detail. The increased clarity allows the user to identify issues more precisely and distinguish small temperature differences. In an industrial setting, for example, a thermal camera with high resolution can detect minor overheating of electrical components, which a camera with lower resolution might miss. For applications that require accuracy and detail, investing in cameras with a high resolution is essential.

What is the Difference between Thermal cameras and Infrared Cameras?

Thermal cameras and infrared camera are sometimes used interchangeably. However, the two are very different. Thermal cameras detect and visualize the infrared energy emitted from objects, producing thermal images which represent temperature variations. Infrared cameras, on the other hand, can include a wider range of devices which capture infrared radiation, such as those used for night vision and surveillance. Thermal cameras are limited to thermal radiation, while infrared camera can also capture reflected light. Understanding the differences between thermal and infrared cameras can help users choose the right technology for their application.

Conclusion

Thermal imaging has revolutionized many industries. It is a powerful tool for detecting temperature changes and visualizing heat.

Thermal cameras are more accurate than standard infrared camera because they detect the infrared emitted from objects.

They are essential for many fields, including building inspections and electrical system monitoring.

Thermal imaging has many advantages but it’s important to know its limitations.

Thermal scans can be affected by environmental factors like emissivity and humidity. They also reflect surfaces and require expertise and calibration to interpret correctly.

To ensure that this technology is used with realistic expectations, it’s important to address common misconceptions. For example, the idea that thermal cameras are able to see through walls.

Consideration should be given to factors such as resolution, temperature range and advanced features when selecting a camera for thermal imaging. These are important in matching the application requirements.

Thermal imaging can be used to improve safety, efficiency and preventative maintenance.

Thermal imaging will continue to grow in importance as technology advances. It is expected to be used more and more to advance diagnostics, energy management, and security across many industries.